Kenyelletso ea Feme ea Mechini e Etsang Roll ea Zhongke

Zhongke press watt mochini fektheri moea oa "batho ba sekametseng, boqapi le 'nete" molao-motheo, ho "boleng ba pele, moreki pele, tšebeletso ea boleng, ho latela konteraka" ka morero, ka matla a matla a moruo, mokhoa o tsoetseng pele oa tsamaiso, matla a matla a tekheniki, mekhoa ea tlhahlobo e phethahetseng le mokhoa o tšepahalang oa ho netefatsa boleng, o inehetseng ho fa bareki ba rona tšebeletso ea boleng. Re amohela ka mofuthu bareki ba bacha le ba khale ho etela fektheri ho tataisa mosebetsi. Re labalabela ka tieo ho sebetsa le uena ho theha bokamoso bo betere!

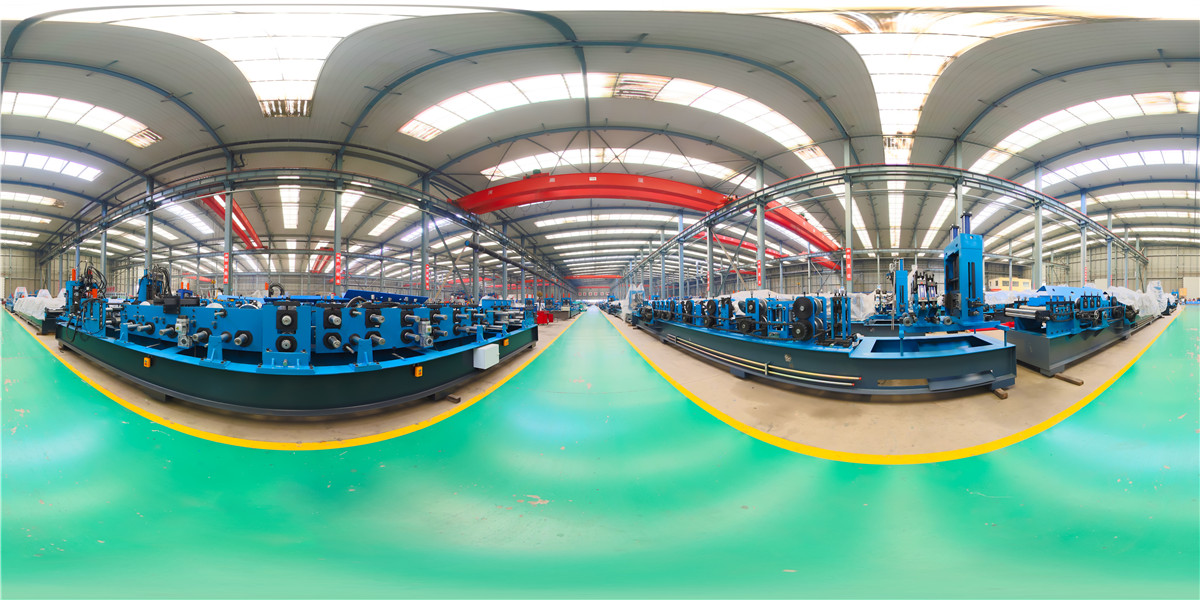

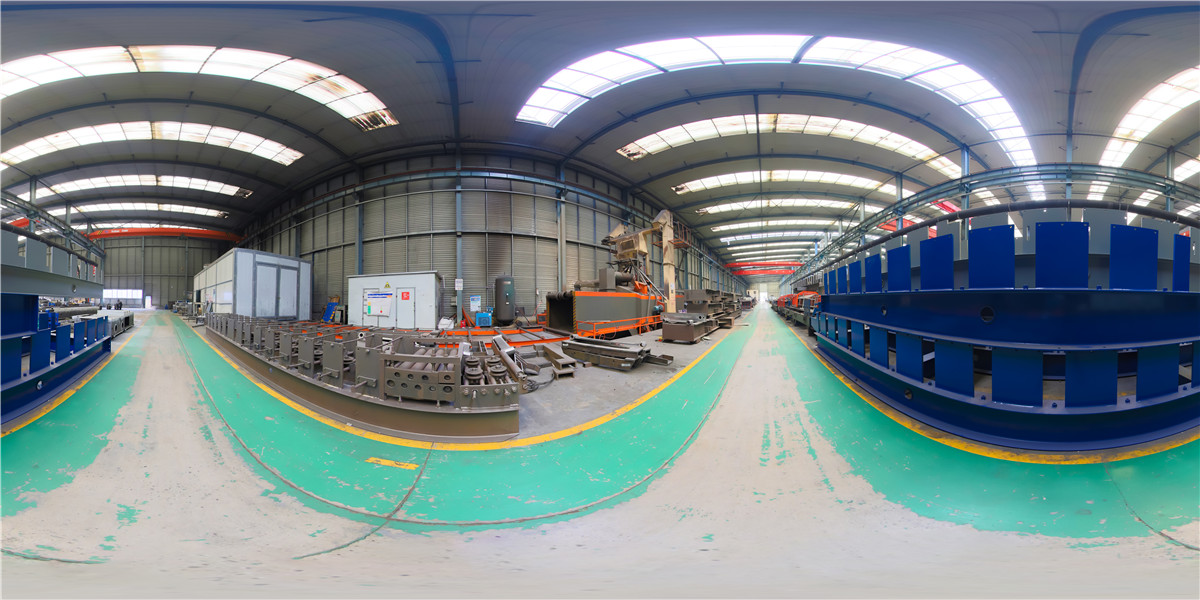

Botou zhongke Roll Forming Machine Factory e thehiloe ka 1996, ke setsebi sa tlhahiso ea mechine e boima le lisebelisoa tsa likhoebo tse kholo. Kamora lilemo tsa nts'etsopele, joale re se re ntlafalitse ho ba pokello ea lipatlisiso tsa mahlale, nts'etsopele, tlhahiso, thekiso, tšebeletso ho e 'ngoe ea likhoebo tse kholo. Lihlahisoa tsa rona li koahela likarolo tsohle tsa mechine e boima le lisebelisoa, 'me li boemong bo ka sehloohong indastering ea mechine e boima. Lihlahisoa tsa rona li amohetsoe hantle ke basebelisi.

Hona joale thepa e kholo ea ho hatisa lithaele tsa haeteroliki e hlahisoang ke k'hamphani ea rona e fihlile boemong bo tsoetseng pele ba machaba, haholo-holo sehlahisoa se nang le tokelo ea molao se entsoeng ke k'hamphani ea rona (ZL200910302633.6), e hapileng Khau ea Naha ea Boqapi ba Saense le Theknoloji le Khau ea Naha ea Sehlahisoa se Secha sa Key Key. Sena ha se na karolo ea ho phahamisa feela indasteri ea metjhini e boima ea naha ea rona, empa hape se hapile litlotla tse ngata bakeng sa khoebo ea rona.

Selelekela sa Thepa

Mochine oa khatiso oa lithaelese ke tšebeliso ea phetisetso ea hydraulic, e nang le poleiti ea tšepe, tšepe ea karolo, Angle steel e le lisebelisoa tse tala, ka ho fepa ka mokhoa o itekanetseng, ho etsa, ho itšeha, ho hlobolisa le mekhoa e meng e entsoeng ka litlhaloso tse sa tšoaneng tsa lithaele tsa tšepe tsa mebala. E loketse mefuta eohle ea moaho oa marulelo a mebala ea tšepe ea ho etsa lithaele. Hobane mochine oa khatiso oa lithaele o hokahane ho o mong ka mochine oa ho fetisa metsi oa mechine e 'meli kapa ho feta, o bitsoa hydraulic tile press.

Mokhoa oa ho sebetsa oa mochine oa khatiso oa lithaele ke hore tšepe ea tšepe e romelloa mochine oa ho etsa ka mokhoa oa ho fepa, o tla otlolla poleiti ea tšepe, karolo ea tšepe kapa Angle steel le lisebelisoa tse ling ho theha, ebe joale sekoti se se nang letho se senyeha ka mokhoa oa ho senya. Hobane mochini o amohela phetiso ea hydraulic, e boetse e bitsoa hydraulic tile press. Nakong ea ts'ebetso, oli ea khatello e ka har'a hydraulic cylinder e fetisetsoa ho cylinder ka pompo ea oli ka sepholi sa oli, 'me oli e ka har'a moqomo ea pholisoe ebe e khutlisetsoa pompong ea oli ka tubing. Ho phaella moo, mochine o ka boela oa futhumatsa billet ka mor'a ho futhumatsa le ho pholile. Ka mor'a phekolo ea mocheso, billet e romelloa moleng oa ho itšeha ka lebanta la conveyor. Ka mor'a ho khaola, mohala oa ho itšeha o romeloa sebakeng se ka holimo sa thepa.

Thepa Litšobotsi

1, mochini o na le hydraulic automatic, ka ho atolosoa ha hydraulic cylinder le motsamao oa hlooho e kaholimo le e tlase ea khatello ho fihlela khatello ea lithaele;

2, ts'ebetso ea lisebelisoa e bonolo, tlhahiso ea othomathike, boloka mathata a ts'ebetso ea matsoho le lithaele tsa ho sebetsana;

3, tlhahiso ea mochini ona oa boholo ba sehlahisoa o felletse, o loketse mefuta eohle ea tlhahiso ea mofuta oa lithaele;

4, mochini o nka mokhoa o hatellang oa ho bopa, o ka netefatsa ho nepahala le ho ts'oana ha boholo ba lithaele, katleho e phahameng ea tlhahiso, litšenyehelo tse tlase tsa basebetsi;

5, mohaho oa thepa o kopane, o koahela sebaka se senyenyane;

6. Boemo bo phahameng ba ho iketsetsa thepa, ho boloka litšenyehelo tsa basebetsi;

7, thepa e koahela sebaka se senyenyane, ho kenya ka potlako le ho loketseng;

8, e ka ba le lisebelisoa tsa hydraulic system ho latela litlhoko tsa bareki. Re na le litheknishiene le lienjineri tse nang le boiphihlelo ho rala litlhaloso le mehlala e fapaneng ea mochini oa khatiso oa lithaele;

9, mochini o amohela hydraulic drive le PLC control system, boemo bo phahameng ba boits'oaro;

10, silinda ea hydraulic e le matla a holimo le a tlase a khatello ea hlooho, kahoo tlhahiso e phahameng ea tlhahiso;

11, lisebelisoa li nka ho fepa hlooho ka makhetlo a mabeli le lithaelese tsa khatello, kahoo boleng ba sehlahisoa bo botle. Fektheri e sebelisa lisebelisoa tse fapaneng tsa ts'ireletso (joalo ka braking ea tšohanyetso) ho sireletsa basebetsi le lisebelisoa;

Melemo ea Thepa

1, lisebelisoa tse tsoetseng pele tsa tlhahiso: ts'ebeliso ea phetisetso e tsoetseng pele ea hydraulic, ho nepahala ho phahameng, lebelo la tlhahiso e potlakileng;

2, ho lemoha ho phethahetseng ho bolela: fektheri eohle e sebelisa taolo ea boiketsetso ea microcomputer, 'me e tsamaellana le maemo a machabeng;

3, theknoloji e tsoetseng pele: ho bopa ha hydraulic ha habeli, ka sekhahla se phahameng, matla a phahameng, boima bo bobebe le melemo e meng;

4, tšebeletso e phethahetseng ka mor'a thekiso: lihora tse 24 li bula mohala oa mohala, lihora tse 24 ho fihla sebakeng sa ketsahalo ho fana ka tšehetso ea tekheniki;

5, Sistimi ea taolo ea boleng bo botle: ho tloha ho moralo ho isa tlhahiso, ts'ebetsong ea taolo ea boleng bo felletseng, ho latela maemo a ISO9001: 2000.

6, marang-rang a phethahetseng a thekiso: Feme ka ho theha likamano tse haufi le barekisi naheng ka bophara, kutloisiso e nakong ea matla a 'maraka.

7, boleng ba sehlahisoa sa boleng bo holimo: Ke lema ho khomarela "khotsofalo ea bareki" ka sepheo, ho latela ts'ebetso e tloaelehileng ea ISO9001. Ho thehiloe tsamaiso e tiileng ea boleng ho netefatsa boleng ba lihlahisoa.